Roof Leak Repair in Tuckerton, NJ 08087

Is your roof leaking?

Everybody desires and requires a safe and secure and comfortable location to live. Lots of home repairs might be accomplished over the course of a weekend. Nevertheless, there are some DIY fixes that should not be attempted. A broken, leaking roof is among the most feared house repairs since finding and correcting a leak isn’t usually straightforward.

Discolored or drooping sheetrock, flaking paint, or an apparent drip are all signs of a roof leak. Even a minor undiscovered leak can cause damaged insulation, mildew advancement, and decomposed wood structure. A leak can also move and spread from the initial broken region to another part of your home.

Our Tuckerton Roof Repair and Replacement Contractors can provide fast service!

Contact Us Today to Repair a Leaking Roof at 888-347-0551

Most of roof leaks in Tuckerton, New Jersey are brought on by fairly normal situations that damage your roof.

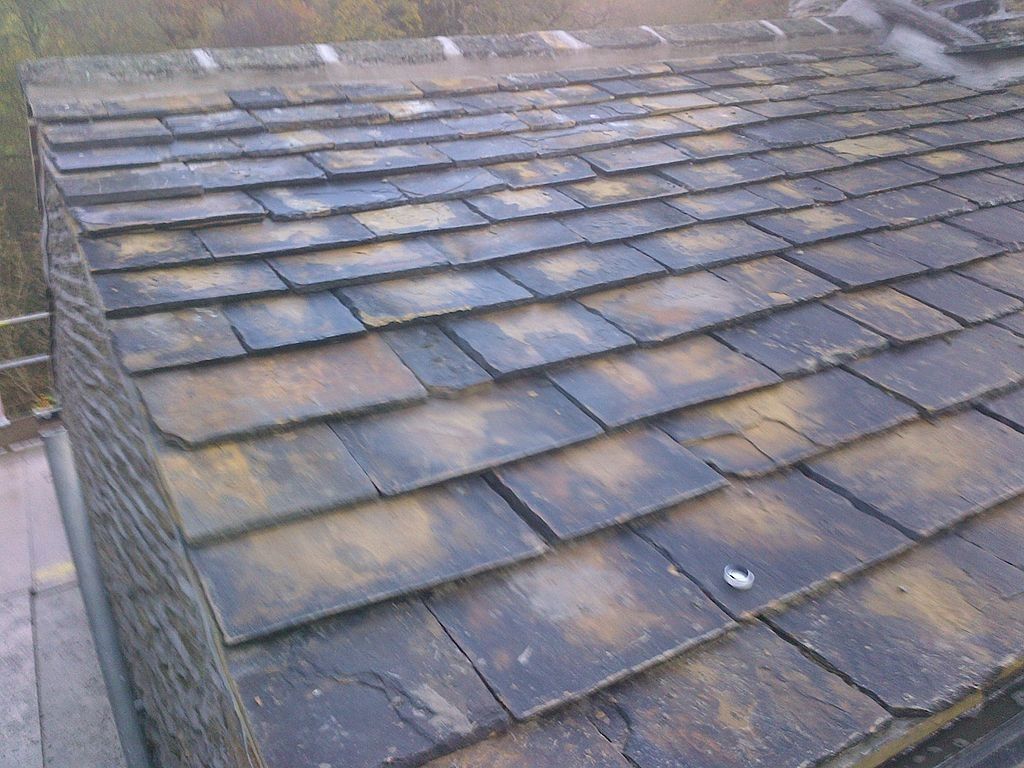

- Your roof will never ever have a bad day, yet aging is unavoidable. All roofing products are prone to extreme climate condition such as rainstorms, freeze/thaw cycles, high temperatures, and extreme summer sun, which may eventually trigger premature aging, splitting, and curling of the shingles.

- Brick chimneys appear to be strong, however the mortar that holds the bricks together, along with the flashing and chimney crown, can be readily ruined. Water may get into the attic through fractures, rust, and leaks.

- A leak can be easily caused by missing out on or broken shingles. Specific shingle replacement is typically not a major concern, but failing to get it repaired might result in more broken shingles and more costly repairs.

- The vents on your roof system include exposed fasteners that will fracture, deteriorate, and age in time. This is a little repair, but it is a common source of leakages due to the fact that most vents do not last the life of the roof.

- The pipes boot slips over a pipe to secure the pipeline’s connection to the roof. The boot, like the vents and flashing, can be damaged, fracture, and stop working. The repair isn’t particularly challenging, although damage can be quickly overlooked.

- Storm damage, strong winds, and hail might all trigger large and small holes. Some holes appear, however others may go undetected for several years till an evaluation reveals them. Water can get in through even small holes brought on by lost roofing nails, the removal of an antenna or meal installing bracket, or impact-related cracks in roofing products.

- A complex, convoluted roofline may be rather attractive, but it is likewise harder to water resistant. Every joint, valley, and slope must be marked.

- Roof materials struggle to withstand freeze-thaw cycles, along with ice and snow. Water might sneak into microscopic areas in between and under shingles when snow collects, melts, and refreezes. Water swells and deepens the fracture as it freezes. The weight of the snow and ice can likewise trigger bending and drooping of the flashing and plywood foundation.

- Gutters may posture troubles if they are not cleaned and fixed on a routine basis. Rainwater can back up behind a clog and penetrate through the shingles, damaging the wood below. Standing water can also trigger damage to older gutters.

- Skylights, like chimneys and pipeline vents, have some of the very same issues. Aside from prospective flashing damage, the rubber or vinyl seals around skylights might dry up and fracture; at this moment, the skylight needs to be replaced.

- Wetness can develop in your attic as a result of ventilation problems, and this can simulate a roof leak. In order to sufficiently leave warm air and moisture from your attic area, your roof should have sufficient intake and exhaust ventilation. This can result in wood rot, mold, and harmed insulation, and it has the potential to be a really pricey repair.

The greatest protection against roof leaks is to schedule a yearly roof inspection and to act quickly if you suspect a leak.

Trusted, dependable roof repair contractors on which homeowners can rely is also a priority. Our Roofing Contractors are dedicated to professionalism and excellent work. Please contact us right away if you need a roof repair contractor at 888-347-0551.

We can provide Emergency Roof Repair for all areas in Tuckerton including: Ocean County, Little Egg Harbor, Little Egg Harbor Twp, Ltl Egg Hbr, Mystic Islands, Mystic Islnds, Leh, Parkertown, Tuckerton Boro, West Tuckerton and in Area Codes 609